Few marketing strategies are as effective as packaging when it comes to coffee. Good packaging may help build brand identification, provide a wealth of information about the coffee, and serve as the consumer’s initial point of contact with a company.

To be effective, however, all graphics, text, and logos must not only be legal, but also distinct and appropriately represent a brand’s aesthetics. This calls for a trustworthy printing technique that works with the selected packaging materials, stays within budgets, and complies with sustainability standards.

Which printing technique is ideal, though? The three most common are discussed, including flexographic, UV, and rotogravure.

Flexographic printing – what is it?

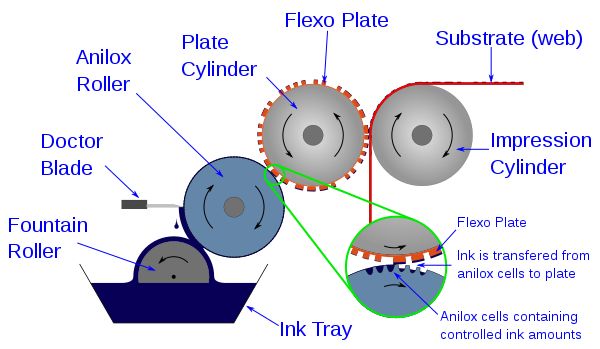

Since the 1800s, flexography, sometimes known as flexographic printing, has been a popular method of relief printing. It entails inking a raised picture on a flexible plate before impressing it onto a substrate (material surface). Rolls of material (or blank stickers) are moved through a series of bendable plates, each of which adds a new color of ink.

Flexography enables printing on both porous (absorbent) and non-porous (non-absorbent) surfaces, including foil and cardboard. These materials can be laminated or embossed without the need for additional production steps, saving both time and money.

Since only one color is printed on each flexography plate, printing accuracy is typically very high. The technology simply processes each material once, making production quick, economical, and scalable. Flexographic printing has a maximum speed of 750 meters per second.

Although the equipment needed for flexographic printing isn’t expensive, it’s complicated and takes time to set up. This means that it is not well suited for short run jobs that require a quick turnaround.

Why pick flexographic printing for the packaging of your coffee?

Flexographic printing excels in block printing because it uses separate plates to apply various colors. These plates need to be changed frequently in between runs.

Flexographic printing is therefore appropriate for companies that are just starting to package and sell their coffee. If roasters want to package and sell their coffee fast and affordably, a single, large print run using one color and basic graphics/text is an excellent choice.

UV printing.

In UV printing, a surface is digitally printed with liquid ink that dries instantly to a solid. In a photomechanical technique, LED printers and UV light assist the ink cling to the surface and produce an image by evaporating the ink’s solvents.

The ink produces a photorealistic, high-resolution finish with precise edges and no bleeding or smudge because it dries instantaneously. Additionally, it offers printing in cyan, magenta, yellow, and black in full color. Additionally, it can print on practically any surface, even non-porous ones.

UV printing is more expensive compared to other types of printing because of its greater print quality and quick turnaround.

Why pick UV printing for the packaging of your coffee?

Although UV printing may be more expensive than other printing techniques, the advantages are endless. The low environmental effect of specialized roasters is one of their main draws.

It uses less electricity since it doesn’t need mercury lamps to dry the ink and doesn’t use volatile organic compounds (VOCs), a byproduct of inks that contaminate the environment.

Micro roasters now have exclusive options to print distinctive coffee packaging with a minimum order quantity (MOQ) of 500 items thanks to UV printing. Because custom-made rollers are needed for flexographic and rotogravure printing techniques to print graphics on packaging, producers typically set MOQs much higher to compensate production expenses.

However, there is no such barrier with UV printing. Custom packaging can be manufactured in small quantities without costing the manufacturer anything. Because of this, roasters who offer microlot or limited edition coffee can benefit by ordering just 500 bags rather than in bulk.

Rotogravure printing – what is it?

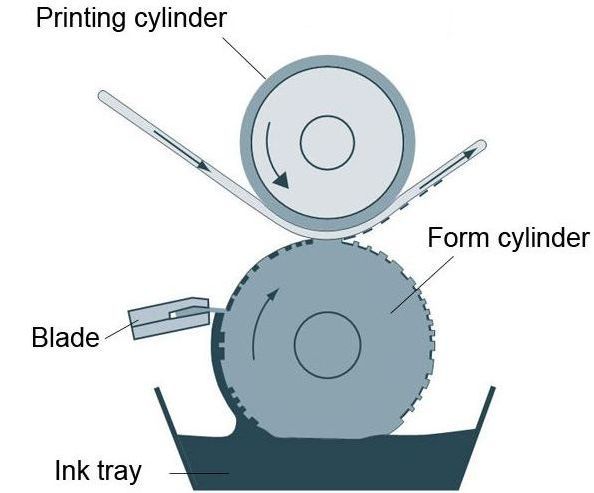

Similar to flexographic printing, direct transfer is used in rotogravure printing to apply ink to a surface. It accomplishes this using a printing press that has a cylinder or sleeve that has been laser etched.

Cells in each press hold ink in the dimensions and patterns necessary for the image. These inks are then discharged onto a surface by pressure and rotation. A blade will remove surplus ink from areas of the cylinder as well as those that don’t need it. Repeating the process after the ink has dried will allow you to add another ink color or finish.

Rotogravure printing generates higher quality images than flexographic printing because of its superb printing precision. The more it is used, the more cost-effective it becomes because its cylinders may be reused. It works very well for printing continuous tone images quickly.

Why should your coffee packaging be printed using rotogravure?

As rotogravure printing often produces printed images of higher quality with greater detail and precision, it may be thought of as a step up from flexographic printing.

Despite this, the quality of what it produces isn’t as excellent as what UV printing produces. Additionally, individual cylinders for each printed color must be purchased. It might be challenging to repay the cost of an investment in custom rotogravure rollers without planning huge volume runs.

There is no such thing as a one-size-fits-all printing solution. The optimal printing technique for a specialty roaster’s packaging will ultimately depend on the needs of that roaster.

Investigate consumer preferences for eco-friendly packaging, for instance. Before spending money on a complete print run, UV printing can enable you print a limited quantity of recyclable packaging so you can assess the market response.

You might also be seeking for a simple solution to package thousands of coffee bags that you want to sell to cafes and customers. Flexographic printing can produce straightforward, one-color packaging in this situation for a reasonable price.

We can assist if you’re still unclear about the ideal printing choice for your roastery. With years of experience serving small, medium, and large-scale roasters, CYANPAK is well-positioned to offer advice on what will work best for you.

Post time: Dec-08-2022