The speciality coffee industry is becoming more and more cutthroat.

All branding tools must be used to their full potential in such a fiercely competitive market to make sure a product stands out.

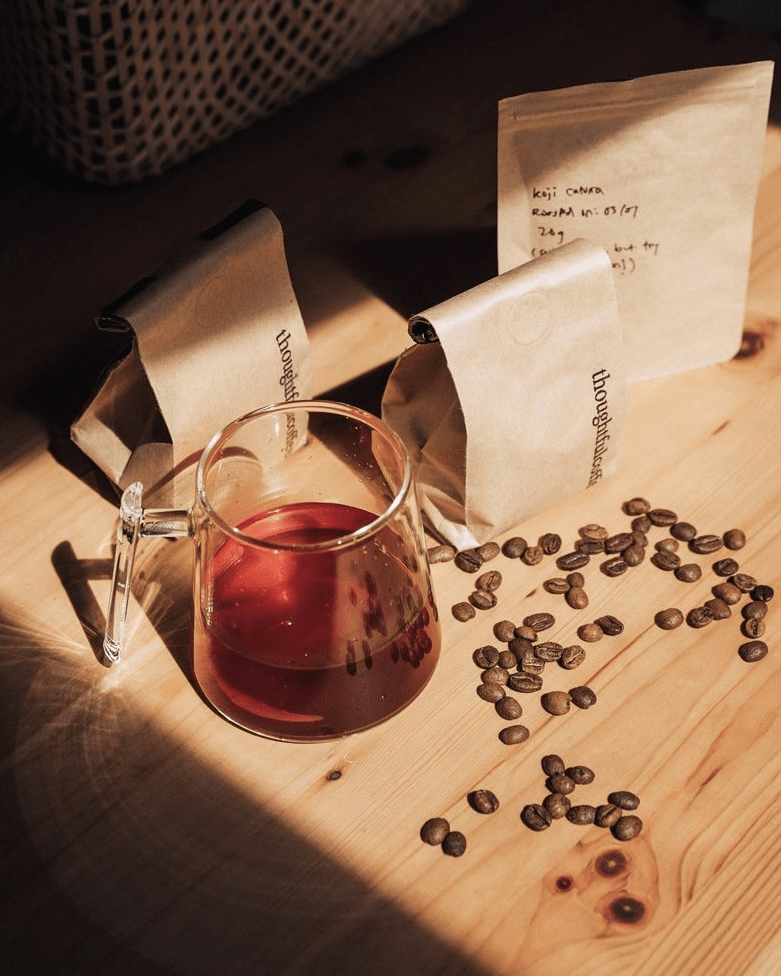

One of the best methods to grab a customer’s attention is with your coffee bag’s design. Additionally, a consumer may be persuaded to buy by the perceived quality of the packing and subsequently, the goods.

Customising coffee bags via hot stamping is becoming more and more common. Without the expense and infrastructure needed for completely bespoke printing, it can help your product succeed.

Continue reading to see how hot stamping might raise the perceived value of your coffee offerings.

Describe hot stamping.

Hot stamping is a relief printing process that was created in the 19th century and has been applied to several design projects ever since.

A printed design is applied to the package material or substrate in this straightforward process.

The design that will be imprinted on the substrate must be printed on a die or printing block, which must be created. Traditionally, the die would be carved out of silicone or cast from metal.

However, cutting-edge 3D printing technologies have made it possible to construct extremely complex designs more quickly and for a far lower cost.

The die is secured into a straightforward two-way press during the hot stamping operation. Next, the substrate or packing material is added.

The substrate is then placed between the plate and a sheet of foil or dried ink. The die pushes through the printing media and transfers the design to the substrate below when pressure and heat are applied.

Since over 200 years ago, relief printing has been practised. The method was first employed by bookbinders to print and emboss leather and paper in the book publishing industry.

Hot stamping became a well-liked method of printing graphics onto plastic surfaces as mass-produced thermo-plastics entered packaging and design.

It is currently widely utilised in a variety of industries, most notably on coffee bags, wine labels, cigarette packaging, and premium perfume companies.

Businesses in the coffee sector are constantly seeking for ways to differentiate their identity in a market that is becoming more and more crowded.

One method for doing this is through hot stamping packaging. Hot stamping is expected to expand at a compound annual growth rate of about 6.5% during the following five years, according to market forecasts.

What kind of materials work best for packaging while hot stamping?

The process of hot stamping is rather forgiving when it comes to the selection of substrate packaging materials.

Notably, the method’s adaptability and flexibility to accommodate changing tastes in packing materials are reasons why it has endured in popularity for such a long time.

Kraft paper coffee bags and sleeves, flexible packaging materials like polylactic acid (PLA), and cardboard coffee boxes all perform well with hot stamping.

Metallic foils or matte-dried inks are the two main types of colours available. It’s important to keep in mind that the ideal decision will depend on both the packaging materials you use and the aesthetic of your design.

For instance, matte inks go nicely with natural kraft paper coffee packaging for a stylish, simple look.

Alternately, hot stamping with metallic foils can go nicely with debossed designs on customized coffee mailer boxes for something more daring or opulent.

Custom coffee boxes with hot stamping have been successful when used to advertise micro-lots or limited edition runs. The method tends to make the goods feel upscale and may help to support a higher price point.

Recycled cardboard boxes can be a simpler substrate to work with for hot stamped foil designs that call for deeper debossing. This is because the substance can reach deep physical depths.

It’s crucial to think about how any modifications you make to the packaging or any other component of your product’s design may affect the environment.

What to take into account before hot stamping coffee bags

There are a few extra factors to think about while hot stamping coffee bags.

The hot stamping technique’s suitability for the brand should come first.

For instance, when it comes to smaller order quantities, hot stamping can be an excellent substitute for fully customized printing.

More specifically, because the minimum order quantities (MQO) are typically lower, it can be a useful strategy for startups and smaller companies. As a result, the technique may adapt more readily to your company’s changing needs.

Hot stamping may support rather complex designs stylistically. Nevertheless, for a full-coverage artist’s creation or anything similar, it might not be the most effective printing technique.

This makes it better suited for minimalist designs, logos, and highlighting specific regions and features of larger projects.

Additionally, designs that are maximalist and have a broad color palette can not work well with hot stamping. It is excellent practice to limit designs intended for hot stamp presses to one or two colors.

Additionally, it’s best to avoid having too many spots where colors blend together. This is due to the fact that colors must be pressed separately and bags’ alignments may change if they are run through the press a second time.

Hot stamping might be able to accommodate stylistically complicated patterns. However, it might not be the best printing method for a full-coverage artwork or something comparable.

This makes it more appropriate for logos, simple designs, and emphasizing particular areas and characteristics of bigger projects.

Additionally, hot stamping cannot be used effectively with maximalist and multicolored designs. One or two colors should be the maximum number of colors used in designs suitable for hot stamp presses.

Additionally, it’s preferable to keep color blending areas to a minimum. This is because colors must be pressed independently, and if bags are run through the press a second time, their alignments may vary.

They can therefore be used with the assortment of eco-friendly packaging options offered by Cyan Pak.

Contact our staff for more details about hot stamping environmentally friendly coffee packaging.

Post time: Jun-15-2023