The ideal printing techniques for each specialty roaster’s packaging will depend on their unique set of requirements. Printing plates are frequently used, and up until recently, printers had no other choice.

Ink is transferred to the printed material in classic printers using printing plates. Because individual plates are used, customizing print jobs can be challenging because the printer setup needs to be changed. Additionally, many plates must be used to add color to coffee packaging, making conventional printing techniques unsustainable.

Many printers still utilize printers with traditional printing plates in spite of the development of digital printing technology. This is due to the fact that they are still a reasonably priced piece of machinery that produces prints of excellent quality.

Many are, however, raising concerns about the sustainability of printing plates as the speciality coffee sector continues to prioritize environmentally friendly packaging.

What are printing plates?

A printing plate is made out of a solid sheet, usually made of aluminum.

The image that is being printed is etched into the flat, thin sheet. The plates are etched using acids, computer-to-plate (CTP) equipment, or laser technology.

This is typically carried out by the printer, who employs specialized machinery to digitally copy the client’s image onto the plate.

Usually, the color will be more vibrant the deeper the engraving is. It’s important to remember that the design uses one plate for each color.

Therefore, a color design will necessitate the creation of four distinct plates, unless a roaster specifically requests a black and white design. Cyan, magenta, yellow, and “key,” which is black, are the four CMYK colors that will be represented by one of these four plates.

The colors are changed into a CMYK format after the printer receives the design files. This in turn determines how much of each of the four colors must be used in order to get the desired color in the design.

The inks are then put to each plate after it has been made, and they are subsequently transferred to the packing materials. Then, same procedure is done with each subsequent color.

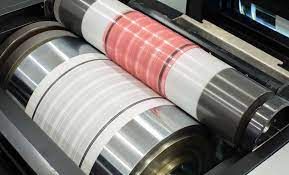

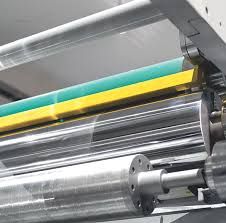

The printer’s cylindrical plate holders, which rotate and press the plates against the printing medium, are equipped with the plates.

Rotogravure and flexographic printing are the two main processes that make use of printing plates.

In rotogravure printing, the printer employs a rotating press with design-engraved cylinders.

Flexographic printing, on the other hand, makes use of printing plates having raised surfaces. Despite being a quicker and less expensive choice, rotogravure printing is better suited for long print runs.

However, each of these processes requires a significant upfront expenditure to produce and etch the printing plates. However, if they are used frequently enough, the cost per unit is rather modest.

A roaster’s versatility is further restricted by printing plates, preventing them from diversifying their bags and producing limited-edition package designs.

As a result, plate-based printing is frequently used by large worldwide coffee companies. The price per unit of this printing technique is much greater for small-scale roasters.

What components go into creating printing plates?

Concerns about the longevity of printing plates exist in addition to the price.

Two factors—the material used to construct the plate and how frequently it is used—can be taken into account to make this determination.

Printing plates are most frequently made of metal, usually copper-plated steel, but they can also be made of plastic, rubber, paper, or ceramics. Naturally, the sustainability of each of these materials varies to some extent.

The least lasting materials are paper and ceramics, which also have the lowest carbon footprints during production. Metal, plastic, and rubber are extremely durable materials, yet their manufacture causes significant pollution.

The best material for their particular use case must be chosen by roasters who want to minimize the environmental impact of their print run.

For instance, paper and ceramics would be the most environmentally beneficial materials to use when printing a small quantity.

However, it would be wise to use more durable materials if this cylinder had to print millions of copies. This prevents the need to replicate several cylinders.

Due to the fact that these plates may be reused, this is a particularly helpful choice for roasters who do not alter their packaging design. A single rotogravure cylinder can be used up to 20 million times, which is noteworthy.

These plates are also simple to clean, allowing for storage until the subsequent print run. Because of this, they are a good, inexpensive solution for large-scale roasters with long print runs.

Additionally, adopting low volatile organic compound (VOC) inks and recyclable packaging materials like Kraft or rice paper would improve the sustainability of this strategy. As well as recycling the printing plate as it reaches the end of its useful life and sticking with the same packaging design.

However, for smaller roasters, digital printing may be more environmentally beneficial than using printing plates.

Basically, the expense or carbon footprint that the four printing plates would produce would not be outweighed by a small number of print runs. Digital printing presents a much more cost-effective and environmentally friendly alternative.

The advantages of eco-friendly printing on coffee packaging

One of the biggest issues facing the coffee business is sustainability. Without it, coffee shop and roastery owners are unable to keep their clientele, safeguard crop yields, or maintain the industry.

Packaging is a good place to start for roasters that want to raise the environmental credentials of their company. There are many advantages to using eco-friendly printing.

It guarantees that roasters are assisting in defending the sector against its most serious challenges and will be crucial in assisting with customer retention initiatives. According to a recent study, 81% of consumers want to patronize sustainable businesses.

According to a linked study, almost a quarter of respondents ceased supporting a company or buying a particular product due to ethical or sustainability-related issues.

Eco-friendly packaging is obviously appealing to a rising number of consumers and can assist ensure that they stay loyal to a brand.

Roasters can increase brand recognition among a wider audience and create a favorable brand impression by making sure a brand is directly associated with sustainability.

Roasters who want to utilize environmentally friendly coffee packaging must take into account both the printing process and the materials. The size of the print run should be taken into account as the primary printing factor.

The most eco-friendly choice for small-scale roasters is to collaborate with packaging experts who use digital printing.

Digital printing techniques use substantially less energy and do not require any printing plates. They therefore cost less and use a lot less raw materials.

Additionally, they significantly lessen their influence on the environment. Notably, compared to rotogravure and flexographic printing, the HP Indigo Press 25K has an environmental effect that is 80% lower.

Furthermore, coffee roasters can further lessen their carbon impact by selecting a printer that offers environmentally friendly coffee packaging materials.

For the first time, independent roasters now have access to customized coffee packaging that is both affordable and sustainable thanks to recent developments in digital printing technology.

Coffee packaging may be designed specifically and digitally printed at CYANPAK with just a 40-hour turnaround and a 24-hour shipment time.

Furthermore, regardless of size or material, we provide low minimum order quantities (MOQs) for packaging. We can also guarantee that packaging is entirely recyclable or biodegradable because we provide bags made of environmentally friendly materials including kraft and rice paper, as well as bags lined with LDPE and PLA.

Post time: Dec-06-2022